The Use and Benefits of Diamond Abrasive Tools

The diamond abrasive tool is made of diamond particles as abrasive grains, and the binder is composed of powders of various metals or metal compounds, which are sintered at high temperature. Its composition is reasonable, the abrasive grains and the bonding agent are firmly bonded, and not easy to fall off during use. It has a long service life and can be used to process all kind of hard materials and improve its processing accuracy, especially for automatic granite polishing lines with good sharpness, strong grinding force, good wear resistance and high comprehensive cost performance.

The use of diamond abrasive tool have the following advantages:

High efficiency

Due to the super sharpness and wear resistance of the diamond abrasive tool, the rotation speed of the conveyor belt can be stably increased, thereby increasing the productivity

Power saving

The super sharpness of the diamond abrasive tool can be used to grind the stone. Because the pressure of the grinding head can be greatly reduced, and the mechanical wear is reduced. At the same time, processing the same thickness of the plate can reduce the stone damage rate, and it can also process thinner stone plates.

High luminosity

The luminosity of the stone can be increased by more than 10 degrees with diamond abrasive tool. Due to the advanced production process, the diamond abrasive tool can completely avoid the change of the curing conditions to make the quality of the abrasive tool unstable. Since the diamond production and testing process and the transportation process are stricter than silicon carbide, the uniformity of the diamond particle size is much greater than that of silicon carbide. The possibility of stone scratches and luminosity instability is greatly reduced.

Reliable quality

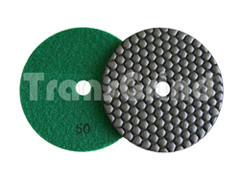

Due to the current large-scale production of diamonds, the price has been greatly reduced, so the price of diamond abrasive tool has also been greatly reduced. In addition, because the production of diamond grinding blocks can adopt computer-controlled production equipment and technology, the quality is relatively stable. TransGrind always focus on producing premium quality diamond tools like trapezoid magnetic PCD tools, EZ change diamond shoes, honeycomb dry flexible pads, etc. All our diamond tooling are factory direct sales, thus we are able to provide quality tools at low prices.

High efficiency

Due to the super sharpness and wear resistance of the diamond abrasive tool, the rotation speed of the conveyor belt can be stably increased, thereby increasing the productivity

Power saving

The super sharpness of the diamond abrasive tool can be used to grind the stone. Because the pressure of the grinding head can be greatly reduced, and the mechanical wear is reduced. At the same time, processing the same thickness of the plate can reduce the stone damage rate, and it can also process thinner stone plates.

High luminosity

The luminosity of the stone can be increased by more than 10 degrees with diamond abrasive tool. Due to the advanced production process, the diamond abrasive tool can completely avoid the change of the curing conditions to make the quality of the abrasive tool unstable. Since the diamond production and testing process and the transportation process are stricter than silicon carbide, the uniformity of the diamond particle size is much greater than that of silicon carbide. The possibility of stone scratches and luminosity instability is greatly reduced.

Reliable quality

Due to the current large-scale production of diamonds, the price has been greatly reduced, so the price of diamond abrasive tool has also been greatly reduced. In addition, because the production of diamond grinding blocks can adopt computer-controlled production equipment and technology, the quality is relatively stable. TransGrind always focus on producing premium quality diamond tools like trapezoid magnetic PCD tools, EZ change diamond shoes, honeycomb dry flexible pads, etc. All our diamond tooling are factory direct sales, thus we are able to provide quality tools at low prices.

Z0OB_%E5%89%AF%E6%9C%AC.jpg)

KG%5D((KQCBF%5B$6E6%5B8US.png)

Comments

Post a Comment